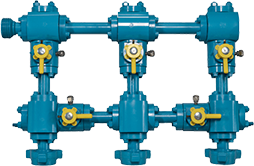

Pigging Valves

PV3 & PV4

PIGGING VALVES

PV3 & PV4

General Information

Sizes ranging from 3” – 12”, Multiple End Configurations Including ANSI CL150 – CL1500 and API 6A.

Share on Social Media

Detailed Specs

PV3 Floating By-Pass Design

Compact body style for bolting between line flanges

During pig loading and retrieving, by-pass design permits minimum of 72 percent of product flow, depending on pipe schedule

No additional tools required for removing or replacing entry plug

Vent/bleeder valve permits the relieving of pressure from the entry pig chamber for safety before removing entry plug

Equalizer valve opens to pressurize entry pig chamber to create low torque operation

Pig launching and removal is performed easily and safely

Back-seated stem prevents blowout

Stem lubrication fitting standard

Locking plates standard

Pig receiver in the ball contains pig stop plate rigidly positioned to stop pig

In-line field repairable

Materials comply with options available for many requirements

NACE MR0175 Latest Edition

Pig entry plug color coded for proper field installation “green” for launching valves “red” for receiving valves

Designed to use spherical style pigs

PV4 Positive Shut-Off Trunnion Design

Trunnion mounted ball for reduced operating torque

No additional tools required for removing or replacing entry plug

Optional body cavity pressure indicator for additional safety

Design is more compact and lighter weight than competitive pigging valves resulting in lower costs

Double block and bleed design

May be used as a positive shut-off flowline valve

NACE MR0175 Latest Edition

Can accommodate bullet and spherical style pigs

Stem lubrication capability standard

Materials available for most media requirements

Pig entry plug color coded for proper field installation. “Green” for launching valves. “Red” for receiving valves